Warehouse Systems

Among or largest projects by volume, was an existing client building a 250,000 square-foot distribution centre in the Greater Vancouver area. The project was a journey from exploration and design, through a full cycle of installation and final grooming. It’s extensive cable rough-in process, lasting some 3 months, was the most involved cable-pull our team has ever undertaken, and involved an immense organization exercise to align with other trades, and interleave with many other build processes that comprised the project as a whole.

Since this project was so complete from beginning to end, we have captured the process in a series of photographic vignettes from stage to stage. The photos, along with the captions provided, offer a walk though from beginning to end for the overall process, and paint a fairly complete picture of the sort of work that drives Xprt Integration.

Phase One: Exploration

The initial stretch of every project we take one is exploratory. We are shown aspects of the project, design to date, and explore client needs at length. We also visit the space and listen to the client or designers involved as they describe their vision for the place. The site visit is a key point in the process where we and the other stakeholders begin to wrestle with the scope of the project, and what could help or derail its success. Exploring this massive facility on a sunny day in late May was a pleasure, and good exercise.

Phase Two: Design

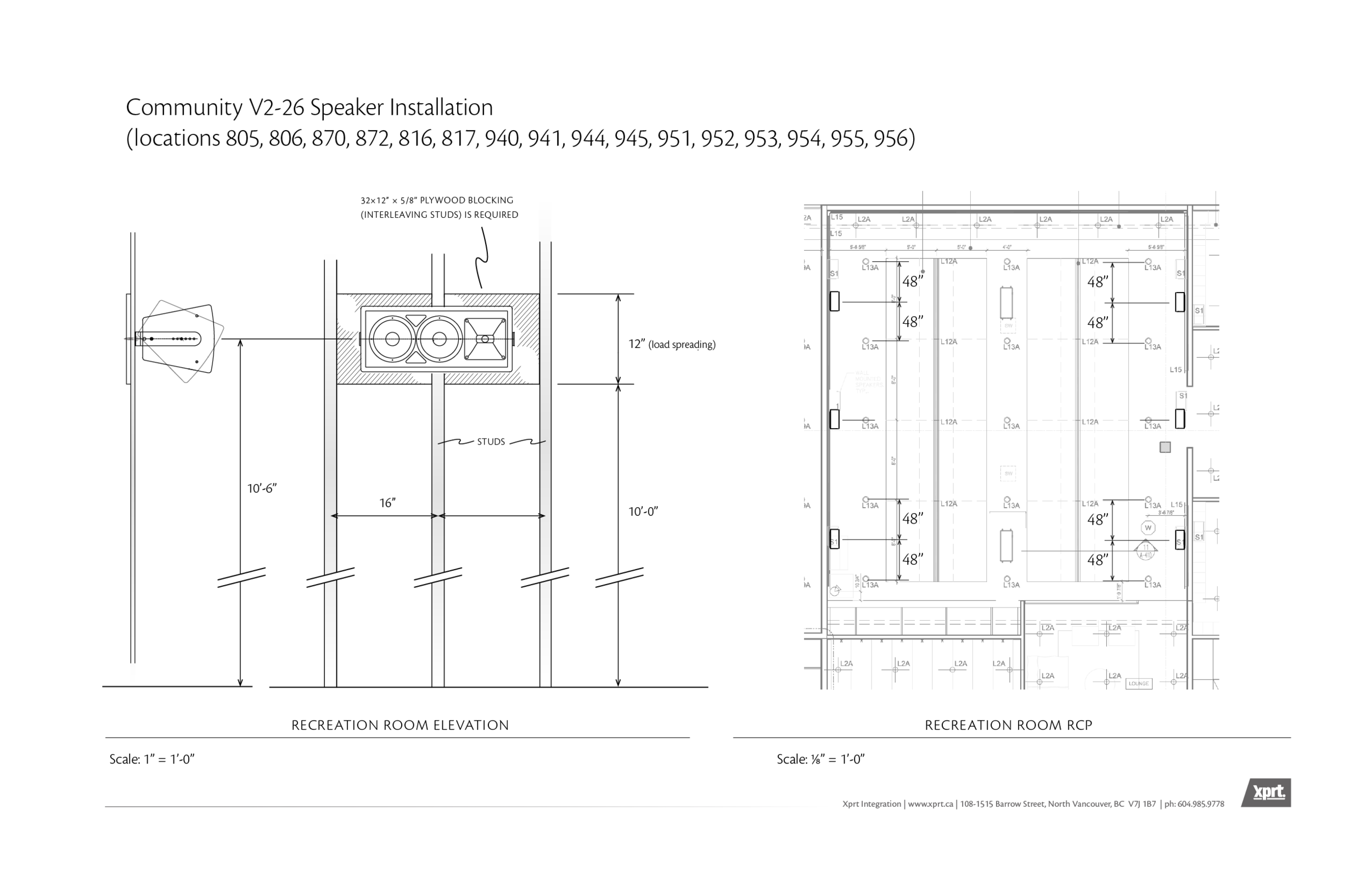

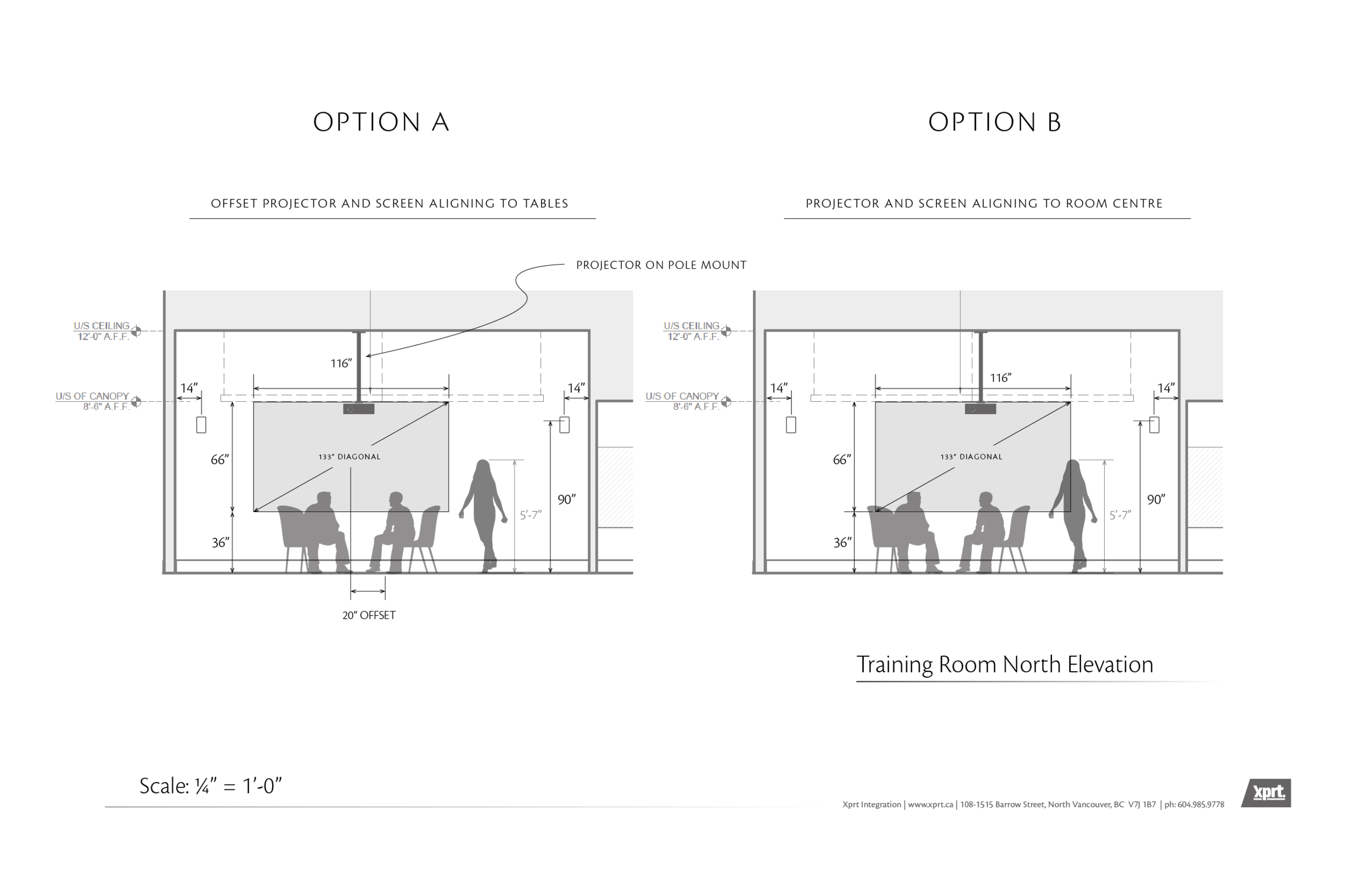

The design phase carried on throughout he project, reacting as needed to changes as the project developed, and adding plates to service specific needs. the design phase also involved a great deal of analysis of the project and drawings to extract the detail necessary to multiply out the efforts and hardware needed.

Design is in the details, and we don’t shy away from delving in. Beyond the architectural plans that we build our Systems Plan on top of, many areas of attention must be described and approved before workers hit the site. Design details allow us to outline and enforce alignment between installation methods, and point to trade dependancies that will need to be met before we can complete our scope. These are just a small sampling of about 90 detail plates that we produced for this project.

Phase Three: Rough-In

The largest segment of the project happens in the thick of interior construction. While walls are being framed, trenches are cut in the concrete slab, and cable tray is and conduit are installed by the electrician in a process taking about 2 months. Cable ‘rough-in’ is a process where we use our detailed cable schedule to plan groups and routes for our cable. It involves knowing where from and two, as well as the role that the cable fills, so that the ends can be left safely for the termination stage. Our team pulling our cable were on site for many weeks executing low voltage rough-in.

Phase Four: Security

A component, more than a phase, Security and Access control systems were a large part of this project. With a plethora of exterior doors, the site needed both an interim construction security system, and a final access control and intrusion alarm system. This effort relied on cabling that was pulled in the Rough in stage, but was then unique from the rest f the project in its installation and configuration. Because of the large scale of the site and extended cable distances, we needed 4 sub panel locations throughout the space to house security components, with network connections running between them.

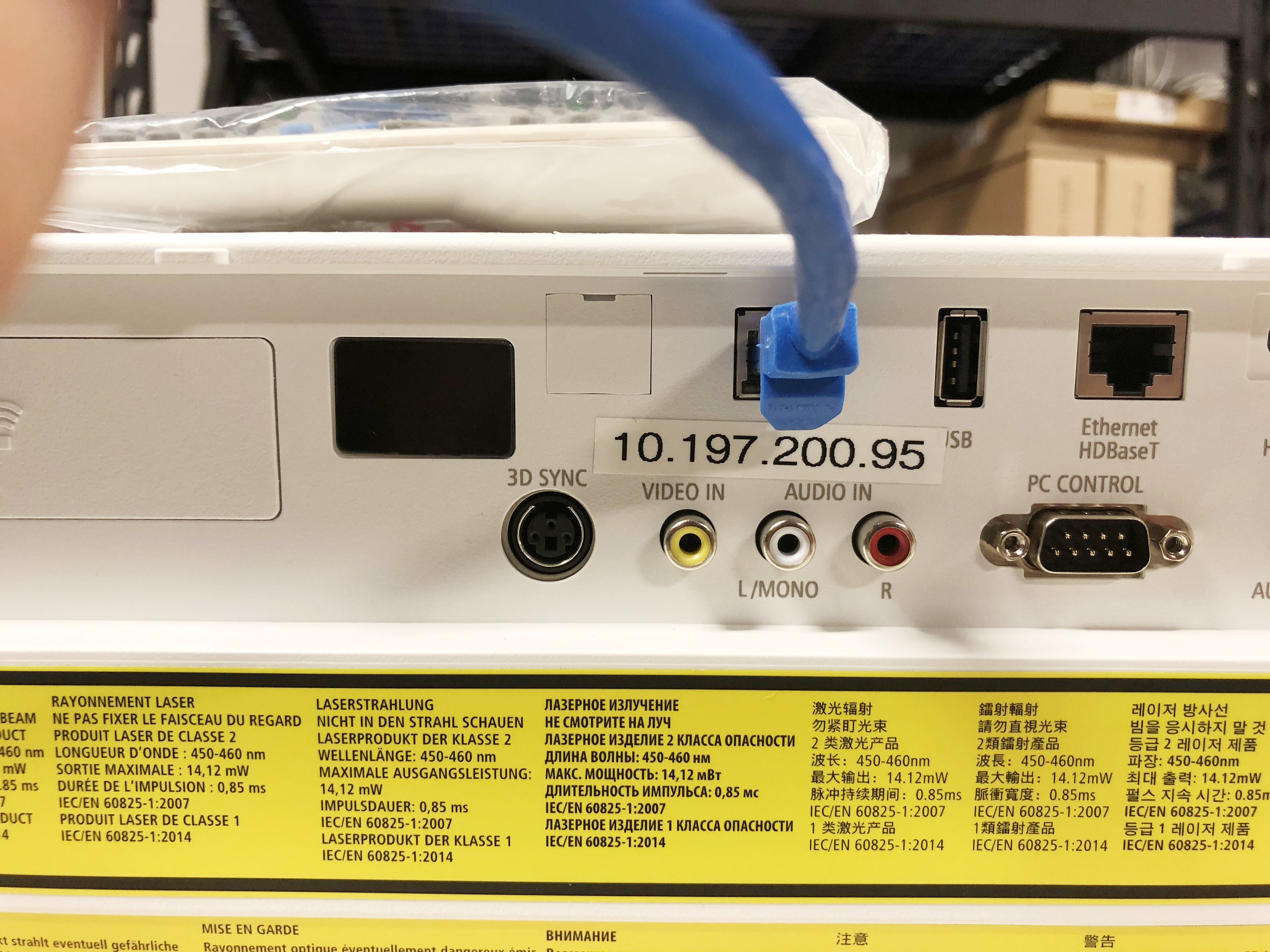

Phase Five: Staging

Staging is the term we use to refer to pre-configuring and testing devices before bringing them to site. Much of our work is logical in nature. We have to program devices, connect devices and configure their intercommunication, confirm settings for devices, and dry run everything to avoid issues arising later on in finishing just prior to hand-off. Xprt’s staging facility is located at our home base in North Vancouver, and our shipping department is kept busy constantly receiving raw items, and shipping stages items to job sites.

Phase Six: Termination

Cables can’t do anything until they have ends that allow them to be connected to components. Happening after board is up, and frequently before a worksite is clean enough fr the actual electronics to be bright in, termination can be a marathon of placing ends on Cat 6 cables, inserting them into straps and them into rings, then placing and labelling faceplates with the cable IDs.

Phase Seven: Finishing

Xprt’s services are full gamut, and as such we handle all the detail down to ensuring users are comfortable with what we’ve produced. Finishing work involves hanging TVs that have already been configured, layout our keyboards, connecting computers, and even setting up POS systems where merchandise is being processed. At this final stage we commission all of the systems, perform final troubleshooting, make any necessary corrections, and even introduce enhancements if desire by our client.

Completion

After a full year of planning, rough-in, staging, termination and finishing, this massive project was successful from the outset. With its fair, and perfectly normal, share of trials and tricks this project had its tedious and tumultuous days, but all of Xprt Integration had their hands on a part pf this project as it was guided to completion. The overlap with the client on this job was an example of thorough collaboration and problem solving that resulted in exactly what was envisioned at the outset. As one of Xprt’s largest efforts of all time, this one job provides an enormous view of what systems integration looks like from the ground up.

As a group, we’re extremely proud of the work that went into this facility.